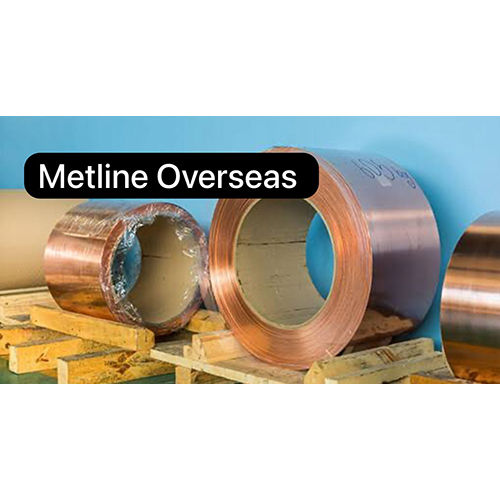

Copper Sheet Coil

990 INR/Kilograms

Product Details:

- Surface Treatment Polished

- Product Type Copper Sheets

- Shape Other

- Alloy Yes

- Grade Etp & Commercial

- Width 16 Inch (in)

- Thickness 0.05 to 1 Millimeter (mm)

- Click to View more

X

Copper Sheet Coil Price And Quantity

- 100 Kilograms

- 990 INR/Kilograms

Copper Sheet Coil Product Specifications

- Yes

- Etp & Commercial

- Other

- Copper Sheets

- Polished

- Brown, Rose Gold

- 0.05 to 1 Millimeter (mm)

- 16 Inch (in)

Copper Sheet Coil Trade Information

- Nhava Sheva

- Cash Advance (CA), Cash in Advance (CID)

- 5000 Kilograms Per Month

- 7 Days

- Export Worthy

- South America, Eastern Europe, North America, Australia, Central America, Asia, Western Europe, Middle East, Africa

- All India

- AN ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018 | PED APPROVED 2014/68/EU

Product Description

Specifications of COPPER SHIM:

| SPECIFICATIONS : | ASTM B152, ASME SB152 |

| THICKNESS SHIMS : | 0.05 To 0.40 Mm |

| THICKNESS HOT ROLLED SHIMS : | 0.02 Mm, 0.02mm To 1.00 Mm |

| THICKNESS SHIMS COILS : | 0.21mm To 5mm |

| MATERIAL GRADE : | C10200,C10300,C10800,C11400,C11600,C14200,C14420 C12000,C12200 |

Premium Copper Coil for Multiple Applications

Experience the advantage of our polished copper sheet coil, designed to meet stringent industrial and aesthetic standards. Suitable for electrical, architectural, and decorative purposes, it delivers durability and remarkable conductivity. With grade options including ETP and Commercial, users can select the ideal coil for their project needs.

Customizable Thickness and Alluring Colors

Tailored to your specifications, our copper coil comes in thicknesses from 0.05 to 1 mm and widths of 16 inches. The alluring brown and rose gold hues, combined with alloying, ensure both performance and a visually striking finish for any application.

FAQs of Copper Sheet Coil:

Q: How can I use the Copper Sheet Coil in commercial and industrial settings?

A: The copper sheet coil is suitable for electrical components, architectural accents, decorative panels, and fabrication work due to its high conductivity, corrosion resistance, and aesthetic polish.Q: What grades are available and how do they benefit different applications?

A: We offer Electrolytic Tough Pitch (ETP) and Commercial grades, allowing you to choose coils with superior conductivity for electrical uses or general-purpose options for architectural and decorative applications.Q: When should I select alloyed copper coils over pure copper?

A: Alloyed copper coils provide enhanced mechanical strength and corrosion resistance, making them suitable for applications where durability and longevity are crucial.Q: Where can I source these Copper Sheet Coils in India?

A: Our copper sheet coils are available nationwide, supplied to exporters, importers, manufacturers, traders, wholesalers, and direct buyers across India.Q: What surface treatment process is applied to the copper coils?

A: Each coil undergoes a polished surface treatment, providing a smooth, reflective finish that enhances both appearance and resistance to environmental factors.Q: What are the key benefits of choosing coils in brown and rose gold colors?

A: Brown and rose gold tones offer a unique visual appeal, making the coils ideal for decorative applications as well as distinguishing binding or electrical components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS