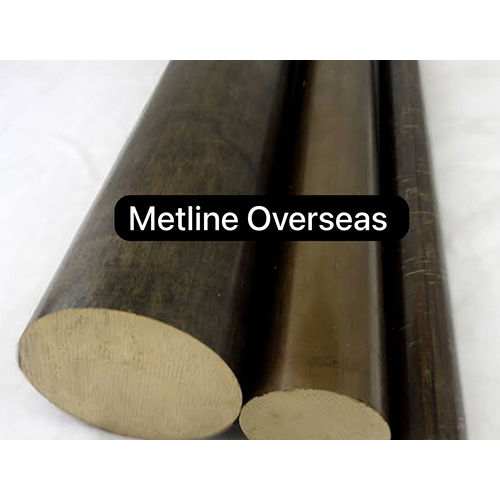

Aluminum Bronze Round Bar

1150.0 INR/Kilograms

Product Details:

- Size 5 mm To 400 mm

- Material Bronze

- Grade CA104, C63000, Ness833 Part2

- Click to View more

X

Aluminum Bronze Round Bar Price And Quantity

- 100 Kilograms

- 1150.0 INR/Kilograms

Aluminum Bronze Round Bar Product Specifications

- CA104, C63000, Ness833 Part2

- 5 mm To 400 mm

- Bronze

Aluminum Bronze Round Bar Trade Information

- Nhava Sheva Port

- v, a, A, ,, , ', d, n, [, ', C, a, s, h, , A, d, v, a, n, c, e, , (, C, A, ), ', C, a, s, h, , i, n, , c, , (, C, e, I, D, ), ', ]

- 5000 Kilograms Per Week

- 2 Week

- No

- Export

- a, r, n, k, a, ', ,, ', ', E, a, h, , [, ', A, l, l, , I, n, d, i, a, ', ,, , ', S, o, u, t, i, a, I, n, d, n, d, i, a, ', ,, ', ,, , ', C, e, n, t, r, a, l, , I, ', , ', W, e, s, t, , I, n, d, i, a, ', ,, , N, o, r, t, h, , I, n, d, i, a, ', ,, , r, a, s, t, , I, n, d, i, a, u, j, ', ,, , ', G, a, t, a, , K, e, d, w, p, ', , ', M, i, z, a, r, a, t, ', ,, , ', K, , D, i, u, ', l, a, ', ,, , ', L, a, k, s, h, a, e, e, ,, M, o, r, a, m, ', ,, , ', M, e, g, h, r, d, e, a, l, a, y, a, ', ,, , ', ', ,, , a, n, i, p, u, r, ', C, h, r, h, ', ,, , ', D, a, m, a, n, , a, ', A, n, d, h, r, a, , P, a, a, n, d, i, g, s, h, ', ,, , ', B, i, h, a, r, ', ,, , G, a, d, h, , ', C, n, ,, , ', l, h, i, ', ,, , ', D, a, d, r, a, , a, n, d, , N, a, g, a, r, , H, a, v, o, a, ', ,, , ', J, h, A, s, s, a, m, ', ,, , ', D, e, s, ', ,, , ', A, a, r, k, h, a, n, d, ', ,, , ', O, d, i, s, h, a, ', ,, , ', P, u, n, j, a, b, ', ,, , ', A, a, n, P, r, a, d, e, c, ,, , ', M, e, l, i, ', ,, , ', n, d, a, m, a, n, , a, n, d, , N, i, c, o, b, a, r, , I, s, l, d, s, ', ,, ', ,, r, y, a, n, a, r, u, n, a, c, h, a, l, , , h, h, a, t, t, i, s, g, a, r, h, ', H, a, ', ,, , ', H, i, m, a, s, m, a, h, a, l, , P, r, a, d, e, s, h, ', ,, , ', J, a, m, u, , a, n, d, , K, a, s, h, m, i, r, ', P, ', ,, R, a, j, a, d, h, y, a, , r, a, d, e, s, h, ', ,, , ', M, a, h, a, r, a, s, h, t, r, a, ', ,, , ', N, a, g, a, l, a, n, d, , ', d, u, ', T, , ', P, o, n, d, h, ,, , t, h, a, n, ', ,, , ', S, i, k, k, i, m, ', ,, , ', T, a, m, i, l, , N, a, ,, , ', e, l, a, n, g, a, n, a, ', ,, , ', T, r, i, p, u, r, a, n, d, ', ', e, s, ', ,, i, c, e, r, r, y, ', ,, , ', U, t, t, a, r, , P, r, a, d, e, s, h, ', ,, , ', U, t, t, a, r, a, k, h, a, W, t, , B, e, n, g, a, l, ', ]

- AN ISO 9001:2015 | ISO 14001:2015 | ISO 45001:2018 | PED APPROVED 2014/68/EU

Product Description

Metline Overseas are Leading manufactures of CuAl10Fe1(CW305G), CuAl10Fe3Mn2(CW306G), CuAl10Ni5Fe4(CW304G), CuAl11Fe6Ni6(CW308G), CuAl11Ni6Fe5, CuAl5, CuAl5As(CW300G), CuAl6Si2Fe(CW301G), CuAl7Si2(CW302G), CuAl8, CuAl8Fe3(CW303G), CuAl9Fe3Mn2, CuAl9Mn, CuAl9Ni3Fe2(CW304G), G-CuAl10Fe, G-CuAl10Ni, G-CuAl11Ni, G-CuAl8Mn, G-CuAl9Ni,C60800, C61000, C61300, C61400, C61500, C61550, C61800, C61900, C62200, C62300, , C62400, C62500, C62580, C62581, C62582, C63000, C63010, C63020, C63200, C63280, C63380, CA104, NES833 Part2, C90200, C90500, C90700, C90710, C90800, C90810, C90900, C91000, C91100, C91300, C91600, C91700, C92200, C92300, C92310, C92400, C92500, C92600, C92610, C92700, C92710, C92800, C92810, C92900, C93100, C93200, C83300, C83450, C83500, C83600, C83800, C83810, C84200, C84400, C84410, C84500, C84800, C92210, C92220, C54400, C95200, C95210, C95220, C95400, C95410, C95420, C95500, C95510, C95520, C95700, C95710, C95720, C95800, C95810, C95820, C95900 LTB1, LTB2, LTB3, LTB4, SAE660, 85-5-5-5, CuNi44Mn1, CuSn4(CW450K), CuSn5(CW451K), CuSn5Pb1(CW458K), CuSn6, CuSn6(CW452K), CuSn8(CW453K), CuSn8P(CW459K), CuSn8PbP(CW460K), CuSn8Pb2P(CW455K),CuSn10, GbCuSn12, GbCuSn12Ni, G-CuSn10Zn, G-CuSn12Pb, G-SnBZ10, G-SnBZ12, G-SnBZ14, G-SnBZ20,G-CuSn2ZnPb, G-CuSn5ZnPb, G-CuSn6ZnPb, G-CuSn7ZnPb, RG-2, RG-4, RG-5, RG-6, RG-7, RG-10, RG-A,G-CuPb10Sn, G-CuPb15Sn, G-CuPb20Sn, G-CuPb22Sn, G-CuPb5Sn, G-PbBz25, G-SnPbBz10, G-SnPbBz15, G-SnPbBz20, G-SnPbBz22, G-SnPbBz5Round Bar, Flat Bar, Hex Bar, Square Bar, Wire Rod, Etc.Exceptional Durability and Strength

Aluminum Bronze Round Bars stand out for their excellent durability and robust mechanical strength. These properties make them ideal for industries where components must withstand extreme stress and environmental wear, such as marine engineering and heavy machinery fabrication.

Wide Range of Sizes and Applications

With sizes ranging between 5 mm and 400 mm, our Aluminum Bronze Round Bars cater to various industrial requirements. The versatility allows them to be utilized in both precision engineering and large-scale manufacturing processes, delivering reliability everywhere.

FAQs of Aluminum Bronze Round Bar:

Q: What are the main grades available for Aluminum Bronze Round Bars in India?

A: We supply Aluminum Bronze Round Bars in grades CA104, C63000, and Ness833 Part2, renowned for their mechanical strength, abrasion resistance, and durability. These grades are commonly utilized in aerospace, marine, and industrial applications.Q: How is the manufacturing process of Aluminum Bronze Round Bars carried out?

A: The manufacturing process involves melting and alloying aluminum with bronze followed by casting, hot or cold working, and precision machining. This process ensures optimal strength, uniformity, and excellent surface finish for sizes ranging from 5 mm to 400 mm.Q: When is it beneficial to choose Aluminum Bronze Round Bars for your project?

A: Aluminum Bronze Round Bars are highly beneficial when your project demands superior corrosion resistance, high strength, and good wear properties, especially in environments exposed to seawater and heavy loads.Q: Where can Aluminum Bronze Round Bars be used effectively?

A: These round bars are used effectively in marine hardware, valve stems, gears, bushings, aircraft landing gear components, and high-performance engineering parts due to their resilience and non-sparking nature.Q: What is the typical usage of Aluminum Bronze Round Bars supplied by Indian manufacturers?

A: Typically, these bars are used for fabricating mechanical components requiring excellent wear resistance and dimensional stability, such as pump parts, bearings, and connectors in shipbuilding, aerospace, and chemical industries.Q: How do Aluminum Bronze Round Bars benefit industrial end-users?

A: Industrial end-users benefit from their long service life, minimal maintenance needs, and ability to perform reliably under harsh conditions, resulting in reduced downtime and lowered replacement costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS